Manufacturing

Manufacturing

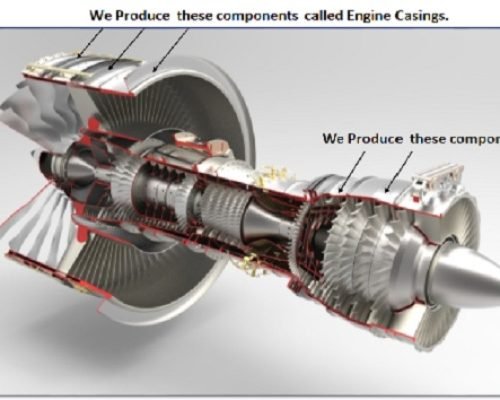

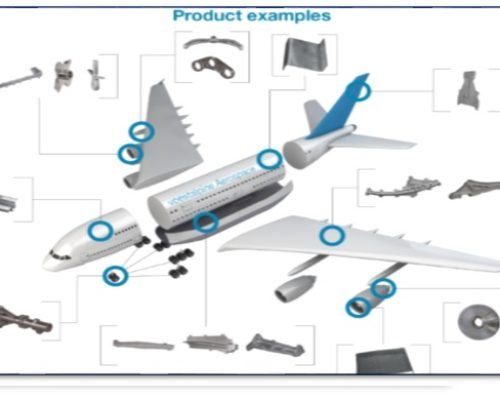

Aerospace machine components

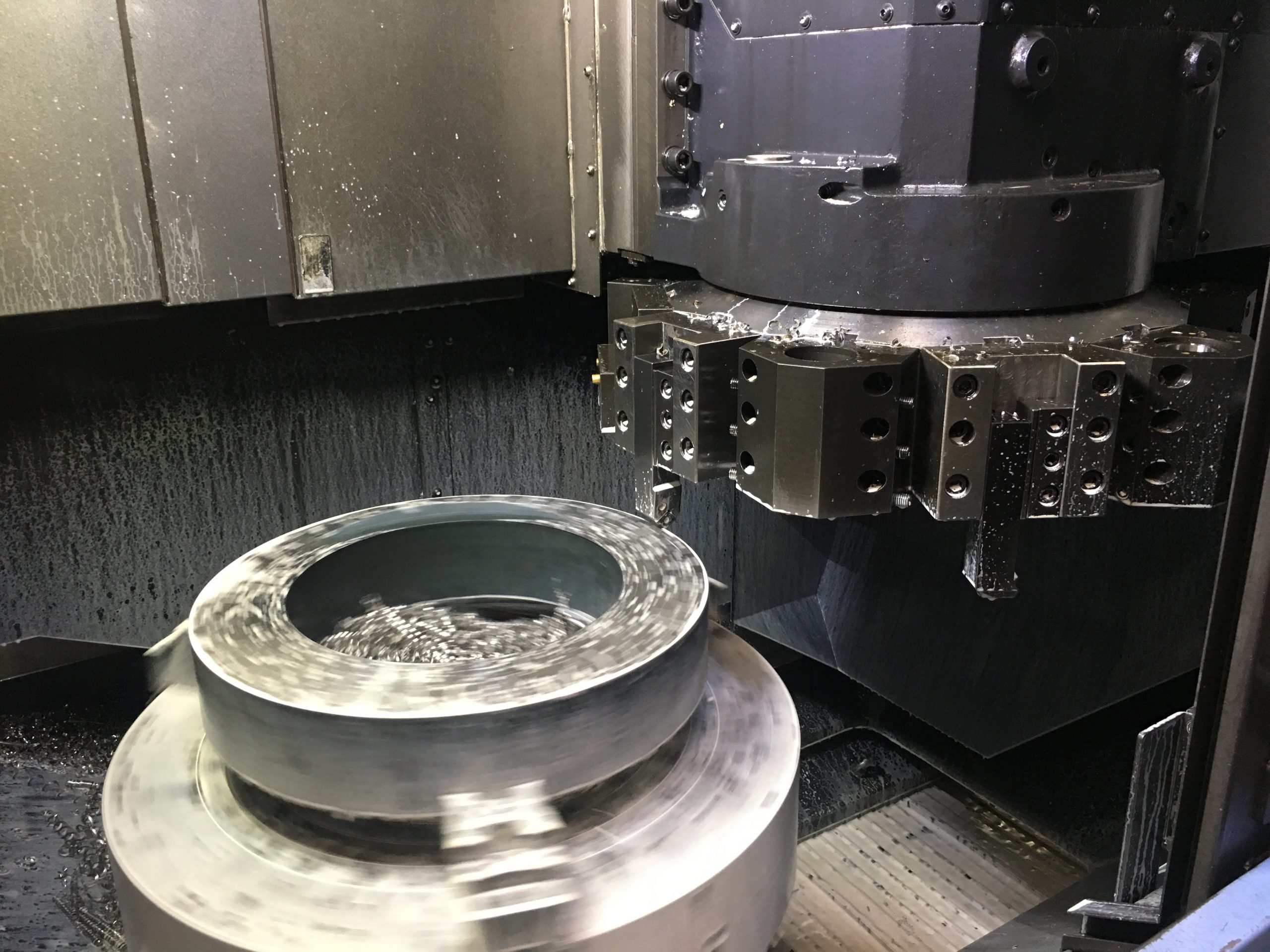

- We manufacture complex machined components for aerospace industries in all types of components in titanium, nickel,Inconal-718, stainless and Aluminium alloys, using its own near net shape starting blanks.

- Manufactures unique fabrications using exotic materials for aircraft turbine engines, space, and ground based applications.We machine components in VMC, Turning, VTL (Vertical Turining Lathe) ,the size ranges up to Diameter 900mm in VTL Turn mill Machine. and maximum length up to 2000mm. Our engineers meet and exceed industry standards, continually revolutionizing the machining process

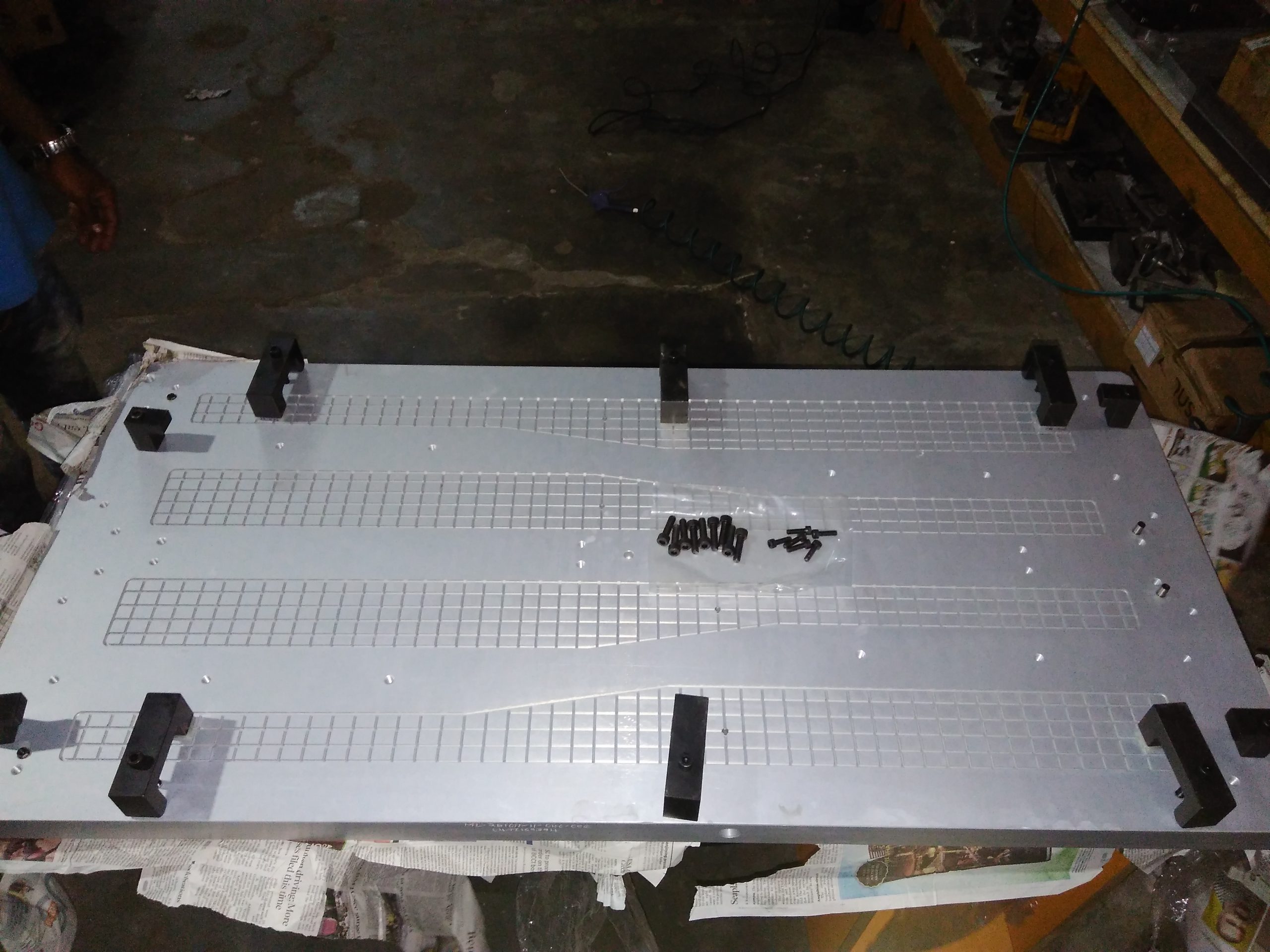

Aerospace Structural components.

- We manufacture high complex structural components for aerospace industry with highly qualified process engineers and programmers. The machining of structural components needs technology oriented machining strategy like planning a lug and several interval setups by building a jigs and fixtures designs.

- The capability of these type of components are up to 4500mm(4.5m) x 3000mm(3m).The components with 5-Axis machining requirements. Also one of our strength to manufacture up to 410mm in diameter.

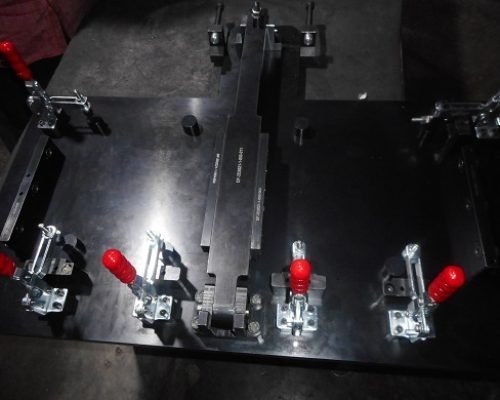

Jigs and Fixtures for Aerospace Industry.

- Jigs and Fixture are one of the most important tool for aerospace components. Along with Machining, We are having our own internal design and manufacturing team for planning and manufacturing the Jigs and Fixtures.

- The jigs and fixture are made with high quality of material with toughened condition to it the requirements.

- The fixtures are designed to suit your machines and operations also with special STD items also can be added for clamping technology.The fixtures are made with several ranges up to 4 Mtr and Diameter up to 1000mm.

Assembly Fixtures

- We manufacture the Assembly fixture, It is a work-holding or support device used in the manufacturing industry. These Fixtures are used to securely locate (position in a specific location or orientation) and support the work, ensuring that all parts produced using the fixture will maintain conformity and interchangeability. Using a fixture improves the economy of production by allowing smooth operation and quick transition from part to part, reducing the requirement for skilled labor by simplifying how workpieces are mounted, and increasing conformity across a production run.

Welding Fixtures

- We manufactures the Welding Fixtures, In many of production process where welding is necessary, high-quality, accurate welding fixtures determine the quality of the final product. A welding fixture is used to position product parts for welding. This secures the geometry of the product parts. When demands with regard to maximum casting are high, or when long welds must be made, the welding fixture should have a cooling function. This is also the case when the material is sensitive to buckling when exposed to heat.

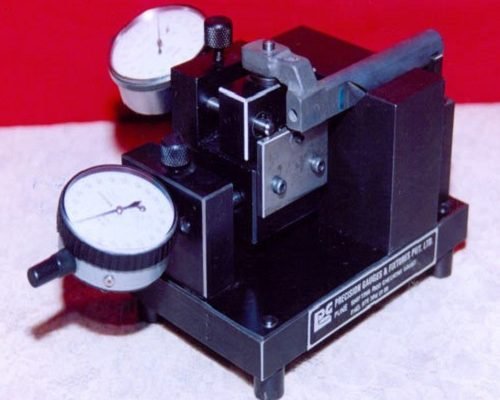

Pipe tooling Oblige Inspection Fixtures

- We Manufacture the Inspection FIxtures & Checking Gauges, Where Inspection is a routine component of the manufacturing process; as parts come off of the production line, some are examined to ensure accurate dimensions. This process requires specialized workholding. Two examples include CMM fixtures and check gauges.

- A coordinate-measuring machine (CMM) is a precision tool that probes multiple points on a part to determine if the geometry is within specification. Check gauges are another form of inspection fixture used to quickly and accurately determine if parts are satisfying basic tolerances. If the part fits into the gauge, the part is within specification.

- These fixtures need to satisfy stiffness and precision requirements, which traditionally would mean they would be custom-machined out of aluminum. However, the process is expensive and depletes valuable shop time. As the effort increases with the complexity of machined parts, it becomes even more cumbersome to manufacture inspection fixtures that must contain intricate geometries.

Checking Gauges

- We Manufacture the Checking Gauges, Where Inspection is a routine component of the manufacturing process; as parts come off of the production line, some are examined to ensure accurate dimensions. This process requires specialized workholding.

Milling Fixtures

- We Manufacture the Milling Fixtures, These Fixtures are usually classified according to the machine for which they were designed. Milling operations tend to involve large, straight cuts that produce lots of chips and involve varying force. Locating and supporting areas must usually be large and very sturdy in order to accommodate milling operations; strong clamps are also a requirement. Due to the vibration of the machine, positive stops are preferred over friction for securing the workpiece. For high-volume automated processes, milling fixtures usually involve hydraulic or pneumatic clamps.

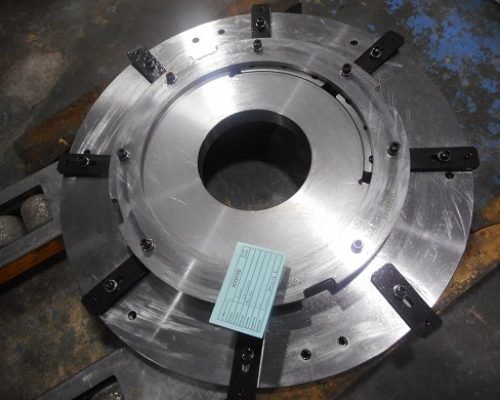

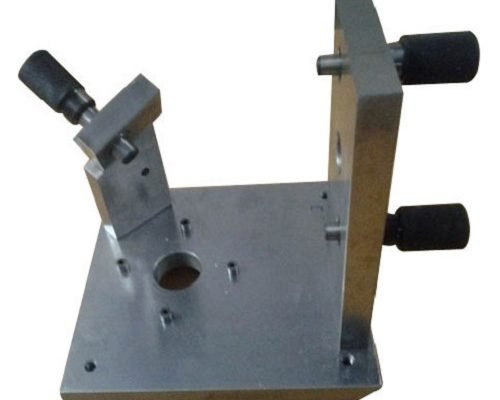

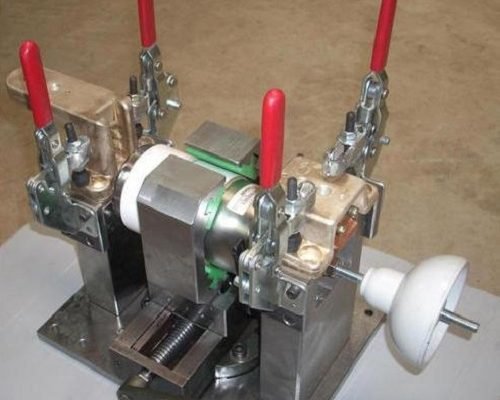

Turning Fixtures

- We Manufacture the Turning fixtures, It consists of a base , location and clamping devices. A Turning fixture can be fixed to the Machine either by holding in the chuck jaws or fixing to a face plate. Basic Design Principles for Turning Fixtures :

- To avoid vibration while revolving , the fixture should be accurately balanced.

- There should be no projections of the fixture which may causes injury to the operator.

- The fixture should be rigid and overhang should be kept minimum possible so that there is no bending action.

- Clamps used to fix the fixture to the Machine should be designed properly so that they don’t get loosed by centrifugal force.

- The fixture should be as light weight as possible since it is rotating.

- The fixture must be small enough so that it can be mounted and revolved without hitting the bed of the Machine.